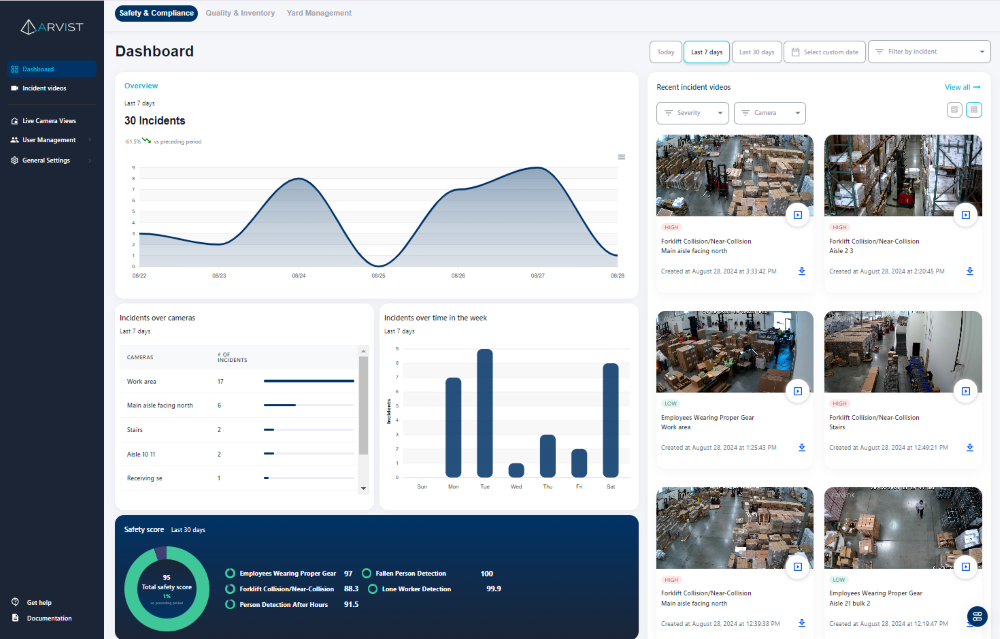

Computer vision AI, connected to security cameras in a warehouse, is transforming the identification of safety and compliance incidents as well as enhancing our overall ability to improve safety and compliance standards.

This new era of technology brings a level of visibility that was never before possible, fundamentally reshaping how we approach safety, efficiency, and the daily operations of HSE professionals.

Unprecedented Visibility: The Game Changer

Historically, identifying safety incidents in a warehouse has depended on manual observation, sporadic audits, or post-incident investigations. These methods often fall short, leaving many risks unnoticed. But now, with computer vision AI, we are entering a new paradigm. By linking AI to existing security cameras, warehouses can achieve a constant, real-time overview of their environment—an advantage that enhances the work of HSE professionals significantly.

As outlined in the DHL Logistics Trend Radar 7.0 –

“Computer vision and AI technologies offer effective solutions for enhancing workplace safety in logistics facilities by monitoring and analyzing movements of people and vehicles in real time. They enable proactive safety decisions, workflow improvements, and prompt corrective actions to mitigate risk and ensure a safer working environment.”

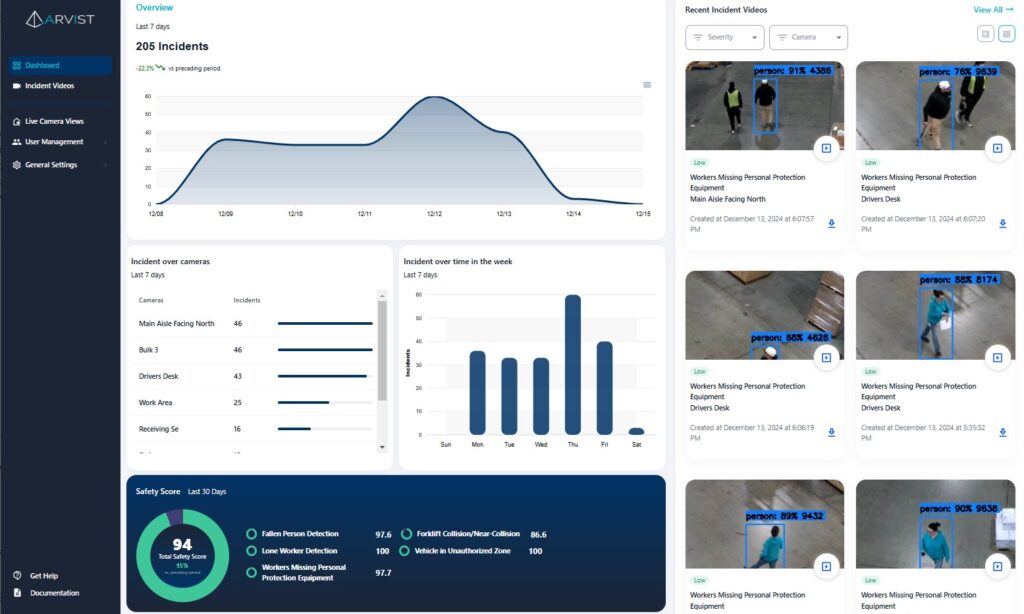

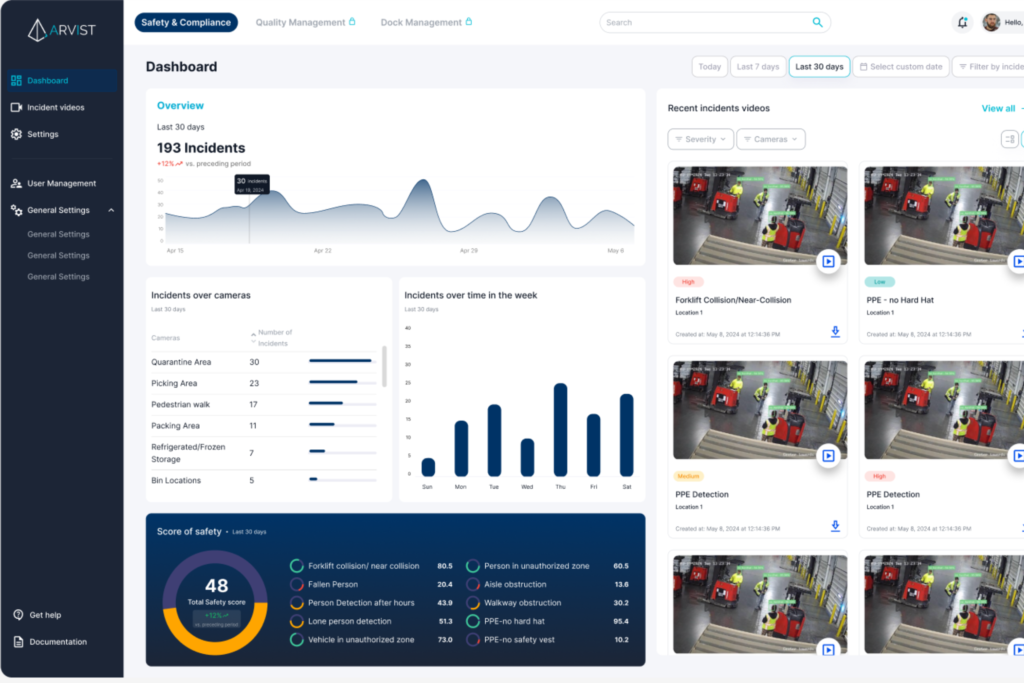

Envision a system that continuously monitors every inch of a warehouse, catching incidents as they occur and even foreseeing potential dangers. From smoke detection to identifying objects in pathways, this technology provides HSE teams with real-time insights, enabling a proactive approach to safety management that was previously unattainable. It offers an unmatched ability to detect everything from the most obvious hazards to the most subtle, fundamentally changing the role of HSE professionals from reactive problem-solvers to proactive safety strategists.

Advancements in Generative AI: Customizing Safety Detection

What makes this advancement even more exciting are the recent breakthroughs in Generative AI, Large Language Models (LLMs), and Large Vision Models (LVMs). At Arvist.ai, we harness these innovations to create customized solutions that align precisely with each warehouse’s unique safety needs, further enhancing the efficiency of HSE teams.

Here are just a few examples of the extensive range of incident detections that can be covered by the technology:

- Cell Phones While Moving: Ensuring safety by detecting distractions on foot or in vehicles.

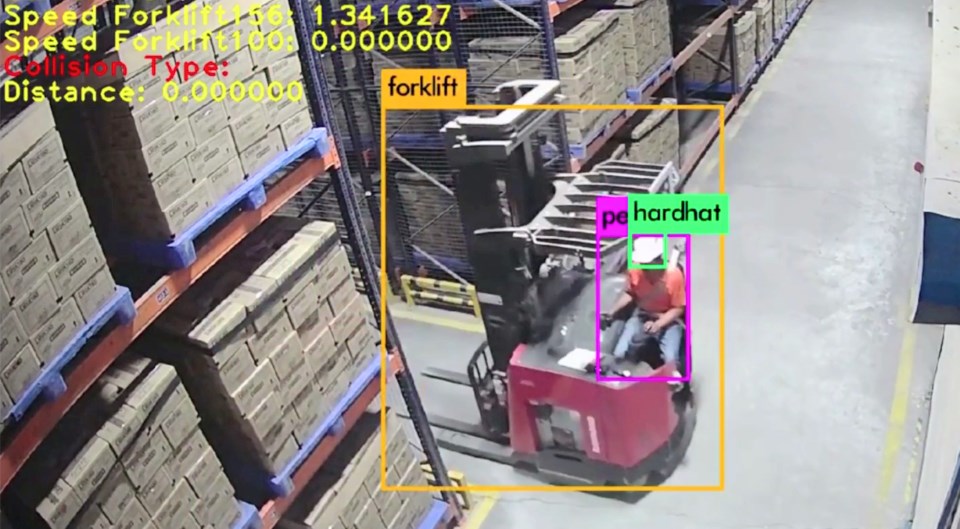

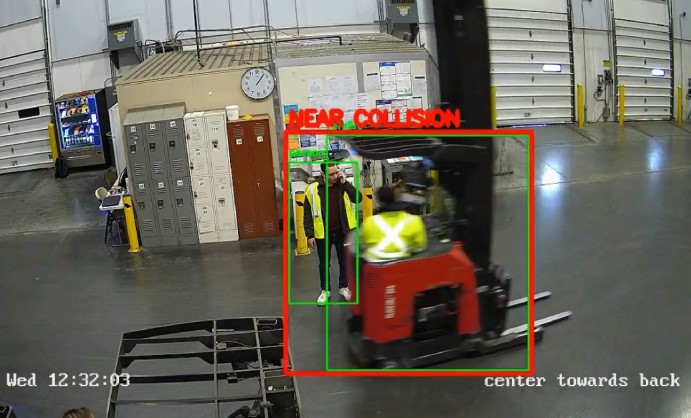

- Forklift Near Collision with Person: Providing immediate alerts to prevent accidents.

- Loitering: Monitoring for unauthorized or potentially harmful behavior.

- Limbs Inside Forklift While Driving: Enhancing safety protocols by ensuring correct forklift operation.

- Driving with Fork Raised Above Knee Height: Preventing dangerous practices with automated warnings.

- No Pushing One Pallet with Another Pallet: Promoting proper handling techniques.

These advancements allow HSE professionals to focus more on strategic safety planning rather than constant manual monitoring, freeing them to proactively address potential risks and create a safer work environment.

A Vision for the Future: Tailored Solutions and Automated Actions

Looking ahead, Arvist’s vision is to empower every warehouse with AI tools that can be tailored to their specific operational requirements. We want to enable our customers, particularly HSE professionals, to define their detection parameters and priorities, creating solutions that are truly personalized and relevant.

We envision taking this even further by linking these detection capabilities to automated workflows that initiate corrective actions when safety incidents occur. For example, if our AI detects a forklift approaching a near collision with a person, it could start a corrective action workflow, such as logging the incident, scheduling a safety review meeting, or notifying the safety team to investigate and implement preventative measures. This type of integration can significantly enhance safety practices, reducing the burden on HSE professionals.

Embracing the New Era with Enthusiasm

Reflecting on these advancements, we are genuinely excited about the future. We are on the cusp of a new era where technology empowers HSE teams and warehouse operators alike to create safer, more efficient workplaces. The ability to see, understand, and act on safety data instantly is no longer just a concept; it is a reality that we are helping bring to life.

At Arvist.ai, we are dedicated to pushing the boundaries of what AI can achieve in the warehouse environment. The journey ahead is full of promise, and we are eager to explore new innovations that will help our customers reach new heights in safety and operational excellence. Together, let’s embrace this exciting new chapter!