AI-Powered Warehouse Safety & Compliance

Your warehouse is a high-risk environment. Manual safety checks are inconsistent, slow, and prone to error. Arvist Vision AI changes the game—monitoring near-misses, enforcing compliance, and preventing accidents in real time using your existing security cameras.

Traditional Safety Checks Fall Short. AI Solves That.

Workplace accidents cost businesses millions in compensation claims, lost productivity, and equipment damage. Manual safety inspections are inconsistent and reactive, leaving warehouses vulnerable to risks. AI transforms warehouse safety by automating hazard detection and compliance enforcement in real time.

Real-Time Hazard Detection and Compliance Monitoring

In a fast-moving warehouse, risks don’t wait. Arvist Vision AI acts as an always-on safety monitor, instantly detecting hazards, unsafe behaviors, and compliance violations before they turn into costly incidents. Whether it’s a forklift moving too fast, a worker without proper PPE, or an obstructed emergency exit, Arvist flags issues in real time and alerts your team to take immediate action. With AI-driven insights, you don’t just spot risks—you prevent them, creating a safer, more compliant workplace without adding manual oversight.

Monitor Near Misses, Reduce Collisions & Improve PPE Compliance

Warehouse safety isn’t just about reacting—it’s about preventing. Arvist Vision AI helps you:

- Identify accident-prone zones to optimize layouts and reduce risks

- Ensure PPE compliance by detecting violations in real time

- Minimize damage costs by reducing collisions between workers, forklifts, and inventory

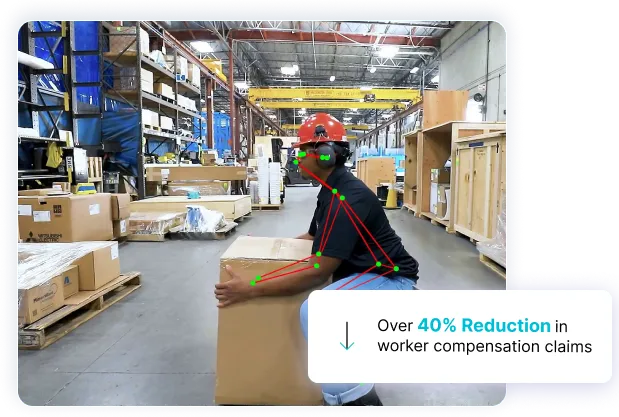

Reduce Workplace Injuries with AI-Driven Ergonomics Assessment

Workplace injuries lead to compensation claims, absenteeism, and long-term health issues. Arvist AI analyzes movements and work patterns to:

- Prevent workers’ compensation claims by identifying and addressing ergonomic risks

- Reduce time off due to injuries by flagging unsafe repetitive motions

- Improve employee well-being with personalized ergonomic training and report.

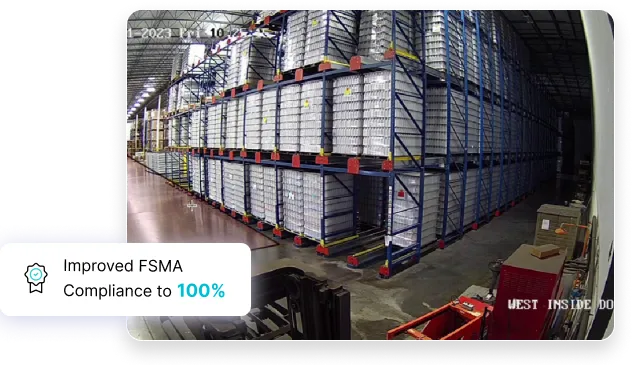

Ensure Compliance in Hazardous and Restricted Zones

Different warehouse areas come with different regulations. Arvist Vision AI:

- Detects violations in bonded warehouses to ensure customs compliance

- Enforces no-code safety rules for hazardous material (HAZMAT) and food safety protocols

- Monitors restricted areas to prevent unauthorized access and liability risks

Safe and compliant workplace = Happy Employees

Improve employee satisfaction and well being with Arvist

Why Choose Arvist’s Vision AI for Warehouse Quality Control

Works With Any Warehouse

From cold storage to distribution centers, Arvist delivers critical safety insights across all warehouse types.

Compatible With Any Camera

No need to buy new hardware. Arvist connects with your existing security cameras or even mobile devices.

Seamless WMS/ERP Integration

Get real-time compliance data directly in the platforms you already use—no extra steps needed.

AI-Driven Insights, Not Just Alerts

Arvist doesn’t just notify you of issues—it helps you understand risks, prevent accidents, and drive real change.

Proven ROI in 60 Days

Clients see significant reductions in workplace injuries, compliance violations, and operational costs within two months.

Scales Effortlessly Across Multiple Sites

Deploy Arvist across all your locations with zero disruptions, adapting to your infrastructure as your business grows.

Why 3PLs choose Arvist?

Automate Quality Checks to meet Highest Standards

At USI, our commitment to excellence drove us to partner with Arvist. Their vision technology has not just met but exceeded our expectations, revolutionizing how we approach safety, compliance, and inventory control. With real-time safety tracking, AI-powered inspections, and automated quality checks, we're not just processing goods; we're ensuring they meet the high standards our clients deserve. This partnership has elevated our operations, enhancing both efficiency and client satisfaction.

Transform Safety & Ergonomics Monitoring

Arvist has done a fantastic job helping Holmatro see opportunities to utilize AI software. They originally came in to help with safety and ergonomics and ended up helping improve our building security and receiving process. They were very patient with us and listen to our needs. The software engineers not only took our information and created something great but they also added features we didn’t think possible. They have really gone above and beyond what we originally thought possible.

Monitor Inbound Traffic Round-the-clock

Arvist helped us design and implement a system to monitor the inbound traffic to our yard using our existing security cameras. We are able to monitor 24/7 now instead of relying on security guards to collect all the information we need. The Arvist team is very constructive and responsive. I really appreciate the effort and progress being made so far.

Previous

Next

Ask the Expert!

Below are some common questions our product experts have received from warehouse managers about how Vision AI can enhance safety, quality, and operational efficiency. If you have any specific questions or need further information, please don’t hesitate to contact us.

AI analyzes real-time footage from security cameras to detect hazards, enforce safety protocols, and identify compliance violations—reducing risks and improving response times.

AI reduces accidents, lowers insurance claims, ensures compliance, and improves overall efficiency.

By identifying risks in real time, AI enables proactive safety measures—ensuring a safer working environment.

Through computer vision and pattern recognition, AI flags potential dangers such as blocked exits, PPE non-compliance, and hazardous equipment operation.

Yes. AI provides automated compliance checks, reducing manual oversight and ensuring adherence to safety regulations.