Maintaining high inventory accuracy is crucial for the success of your business. Failing to keep precise inventory records can lead to significant issues, including financial losses, penalties, and a decline in service quality. These problems can snowball, affecting your bottom line and damaging your reputation within the supply chain.

The Cost of Inaccurate Inventory Tracking

Inaccurate inventory management is more than just an inconvenience; it’s a serious issue with wide-ranging implications. A study by IHL reveals that the total cost of inventory distortion in 2023 is projected at $1.77 trillion.

Inventory inaccuracies can lead to lost sales, excess inventory costs, and fines due to missed delivery schedules. Moreover, inaccuracies in inventory records can result in non-compliance with industry regulations, potentially leading to hefty fines and strained relationships with partners.

Additionally, when service levels drop due to inventory issues, customer trust erodes, making it challenging to maintain long-term partnerships.

Traditional Inventory Practices: Challenges and Limitations

Warehouse managers traditionally rely on methods such as cycle counting, physical audits, and manual entry into Warehouse Management Systems (WMS) to maintain accurate inventory records. While these practices have been foundational for years, they come with significant drawbacks:

- Labor-Intensive Processes: Manual inventory tracking requires a substantial amount of labor, which increases costs and introduces the possibility of human error.

- Inaccuracy in Counts: Errors during manual counts or data entry can lead to discrepancies in inventory records, impacting the overall efficiency of warehouse operations.

- Time-Consuming Updates: Updating WMS or ERP systems manually can be slow and cumbersome, further contributing to inventory inaccuracies.

These limitations highlight the need for a more efficient, automated solution that can enhance inventory accuracy and streamline warehouse processes.

The Vision AI Revolution: Three Key Solutions for Improved Inventory Accuracy

Vision AI is a cutting-edge technology that is transforming warehouse management by automating and optimizing inventory processes. Here’s how Vision AI, particularly as implemented by Arvist.ai, can revolutionize your warehouse operations:

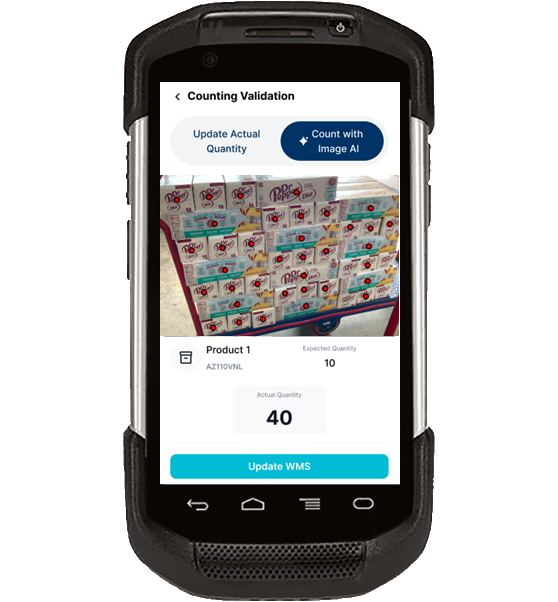

1. Vision AI for Automated Stock Taking

One of the most powerful applications of Vision AI is its ability to automate stock taking, helping to maintain inventory accuracy. Arvist AI offers a mobile app that leverages Vision AI to count items in a bin location with a single image capture. This eliminates the need for manual counting, significantly reducing the time and labor required for inventory audits. The app then automatically updates the WMS or ERP systems with accurate inventory data, ensuring that your records are always up to date.

This solution not only accelerates the stock-taking process but also minimizes human error, leading to more reliable inventory accuracy and better decision-making.

For more details on how Vision AI is revolutionizing warehouse quality control, read our in-depth article.

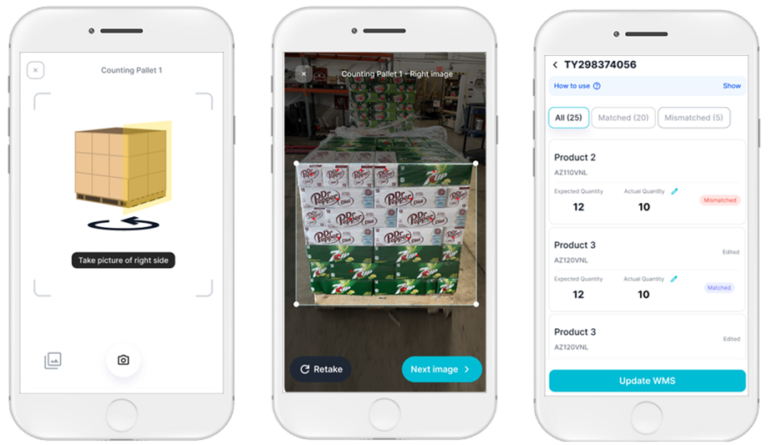

2. Vision AI for Accurate Shipments Processing

Accurate shipment processing is essential for maintaining inventory accuracy. Ensuring that the quantities of goods entering and exiting the warehouse match the manifest is critical to avoiding costly discrepancies.

Arvist’s Vision AI-powered Shipment Processing App automates the counting of products on both inbound and outbound shipments, including mixed-SKU pallets. This technology speeds up the counting process, improves inventory accuracy, and ensures that data is correctly synchronized with the WMS. The result is faster, more precise shipments that align perfectly with your inventory records, thereby improving overall warehouse efficiency.

3. Vision AI for Inventory Operations Tracking

Beyond stock-taking and shipment processing, Vision AI can be employed to monitor inventory operations throughout the warehouse. By integrating Vision AI with security cameras, warehouses can gain real-time visibility into goods movements, ensuring accurate tracking of inventory as it transitions through various stages.

This enhanced visibility improves productivity, efficiency, and overall inventory accuracy, allowing warehouse managers to make more informed decisions and optimize their operations.

Conclusion: The Future of Warehouse Management with Vision AI

Vision AI is not just an enhancement to traditional inventory management practices—it’s a revolutionary technology that’s setting new standards for inventory accuracy, efficiency, and reliability. For warehouse managers looking to improve inventory accuracy, streamline cycle counting, and embrace warehouse automation, Vision AI offers a powerful solution that can transform your operations and drive better business outcomes.

As the industry continues to evolve, embracing Vision AI will be key to staying ahead of the competition and ensuring your warehouse operates at peak efficiency.