Be Global Safety, based in Durham, uses AI to detect workplace incidents in real-time.

As a Global Project Manager for the Denmark-based manufacturing company Danfoss, Nilay Parikh spent a lot of time visiting facilities around the world to help set up advanced manufacturing centers. While visiting dozens of factories, one thing that stuck out to him was how the process regarding employee safety was entirely manual, while other processes like quality assurance were automated.

To Parikh, the pertinent question was obvious: why not use the same vision-based technologies that are used for things like quality assurance to increase employee safety by detecting accidents and near-misses? With that goal in mind, in 2020 Parikh founded Durham-based Be Global Safety—a B2B SaaS startup participating in the latest cohort of the RIoT Accelerator Program (RAP).

The “global” in the name comes from the geography of the team: Parikh is located in Durham, while his other two co-founders—Werner Stapela (Senior Adviser) and Aleksandra Duo (Chief Marketing Officer)—are based in Germany and Denmark, respectively. Werner was Parikh’s manager at Danfoss and also noticed how outdated the safety processes were when visiting over 30 factories around the world with Parikh.

Bharath Kumar, the CTO, brings over 13 years of artificial intelligence experience and is based in India.

Many companies rely on their employees to report safety incidents when they see them, leading to about 80-85% of incidents being completely uncaptured, Parikh found. The problem is that someone can’t always be on the lookout for these accidents or have the time to report them.

“When we talk about all these supply chain issues and labor issues, having an unsafe work environment is really not going to help even from a business perspective,” Parikh said. “And from an employee perspective, definitely they want to go into a workplace where they can feel safe.”

Be Global’s Safety uses AI technology to detect incidents in real time—such as an accident on the forklift, spill on the floor or a worker falling—as well as detecting near-misses and close calls with equipment and vehicles. Because the latter isn’t technically a “real” accident, employees may be less likely to report it. Parikh initially did a proof of concept of the startup’s software at a factory in India and found that it detected almost 20 times the number of incidents that were reported manually.

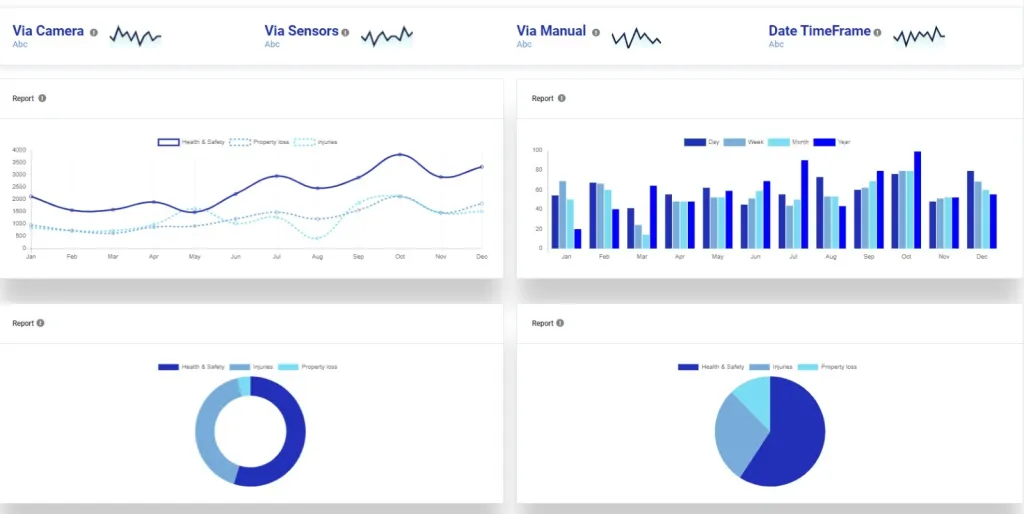

Be Global Safety’s software helps companies detect both accidents and near-misses, as well as provide key analytics to prevent them in the future.

Warehouses, loading docks and sea ports can easily fit the company’s software, which detects close calls with vehicles. The software also utilizes sensors and cameras to detect gas leaks and monitor air quality in a facility, which is important for companies in industries like pharmaceuticals, chemicals or fossil fuels.

Detecting accidents and near-misses is Be Global Safety’s first goal with the technology, Parikh said. The second goal is to use the data to provide analytics to companies to prevent future accidents from occurring. Their software detects usage of personal protective equipment such as masks, hard hats, helmets, gloves and safety suits, which is key for many industries such as automotive and engineering.

Be Global Safety completed an MVP in summer 2021 and is currently offering 30- to 60-day free pilots. After that, customers either pay a monthly subscription fee that depends on the size and number of facilities they have, or smaller enterprises that don’t need as many cameras and sensors can pay a yearly flat fee.

Be Global Safety’s next steps include onboarding more customers from diverse industries and continuing product development, including an upcoming launch of a new feature that analyzes how efficiently people are lifting or operating machinery, so that companies have insight into the ergonomics of these procedures in addition to how safe they are.

Transitioning worker safety from a manual process to an automated process is crucial, Parikh said. In the U.S. alone, there were 15 workplace fatalities per day in 2019 according to the U.S. Department of Labor—and that’s not including the much larger number of injuries.

“For many companies, board meetings start with the safety statistics of the previous quarter,” Parikh said. “So everyone knows that safety is paramount and that their workforce is their critical asset. And Be Global Safety can ensure that what they’re saying can actually be more practical, and we can ensure incident-free workplaces in future.”