In the fast-paced and evolving world of warehouse operations, quality control in warehousing has become a paramount concern for businesses aiming to enhance supply chain visibility and ensure the delivery of perfect orders. With the advent of AI and technologies such as real-time video monitoring and machine vision inspection, the paradigm of ensuring warehouse compliance and minimizing damaged goods is shifting. These advancements offer unprecedented potentials for improving dock to stock times and achieving a higher perfect order rate, positioning businesses at the forefront of warehouse productivity improvement.

The integration of computer vision into warehouse quality control represents a leap toward operational excellence, enabling AI for warehouse management to not just react to issues but prevent them proactively. This article will unravel how leveraging data through technologies like computer vision transforms the landscape of quality control in warehousing. We will discuss the substantial benefits these integrations bring, from enhancing warehouse operations to ensuring damaged goods are identified and dealt with efficiently. Additionally, we’ll look at the challenges that come with adopting these technologies and propose solutions to overcome them, promising a future where supply chain visibility is not just a goal but a reality.

Understanding Computer Vision

Definition

Computer Vision (CV), a pivotal field within artificial intelligence, empowers systems to interpret and understand visual data akin to human vision. This involves processing images and videos to extract meaningful insights. The technology utilizes algorithms and neural networks, specifically deep learning and convolutional neural networks (CNNs), to enable machines to recognize and categorize objects, scenes, and activities from visual inputs

Applications in Different Industries

The applications of computer vision span multiple sectors, demonstrating its versatility and impact. In the automotive industry, computer vision is crucial for developing self-driving vehicles, helping them to interpret road signs, detect obstacles, and navigate safely. The raging debate around whether Tesla or Google has the correct approach to self-driving vehicles stems from the fact that the former believes in the power of computer vision technology while the latter insists on combining computer vision with sensors like LiDAR. The retail sector benefits from computer vision in enhancing customer experiences through smart mirrors and cashier-less stores, significantly reducing wait times and improving service efficiency. Computer vision is also playing a vital role in agriculture, helping monitor crop growth and livestock health, which is essential for efficient farm management. The technology’s ability to analyze visual data also extends to safety enhancements in industrial settings, where it aids in monitoring workers and detecting potential hazards.

These diverse applications underscore the transformative potential of computer vision across various industries, driving advancements and efficiencies that were previously unattainable.

Leveraging Data for Quality Improvement

Data Collection Methods

In the realm of warehouse operations, the collection of accurate data is paramount. Methods such as digital field forms have revolutionized data accuracy by preventing common errors associated with manual entries, such as transcription mistakes and data loss. Additionally, advanced data gathering scanning tools like Zebra Technologies and others offer integration with systems like SAP to enhance real-time data visibility, crucial for maintaining competitive operations. The data management systems like WMS (Warehouse Management Systems) play a vital role in storing and gathering data for purposes other than order fulfillment. At Arvist, we also enable visual data collection using your normal cell phones and tablets and connect the data with the WMS (more on that later!).

Analytics Tools and Techniques

Warehouse management analytics are indispensable for optimizing operations. These tools utilize techniques like data mining and AI to analyze operational aspects, from inventory levels to labor productivity. For instance, predictive analytics can forecast inventory needs, while AI-infused solutions suggest optimal item placements, enhancing efficiency and reducing operational costs. Moreover, inventory management tools provide immediate insights into stock statuses, helping avoid costly stockouts or excess

Incorporating these advanced analytics into warehouse operations allows businesses to transform vast amounts of data into actionable insights, significantly improving decision-making and operational efficiency.

Benefits of Combining Computer Vision and Data

Accuracy and Efficiency

The integration of computer vision in warehouse operations significantly enhances both accuracy and efficiency. By automating the identification and tracking of goods, computer vision minimizes risks such as package loss, theft, or misrouting, thereby ensuring precise inventory levels. This technology facilitates the rapid capture of data upon the receipt of goods, reducing human error and enabling efficient tracking and storage. Furthermore, computer vision supports the optimization of the picking and packing process by suggesting the most efficient routes and configurations, which not only speeds up order fulfillment but also reduces the chance of errors.

Cost Implications

Computer vision technology also plays a crucial role in cost management within warehouse operations. By automating routine tasks, such as the tracking of pallet storage locations and validating loading counts, it reduces the need for manual labor, thereby lowering operational costs. Additionally, the use of computer vision for monitoring equipment and vehicles helps in identifying maintenance needs early, minimizing downtime and extending the longevity of the equipment. This proactive maintenance approach, combined with the technology’s ability to optimize delivery routes based on real-time data, results in significant cost savings and a smoother supply chain operation.

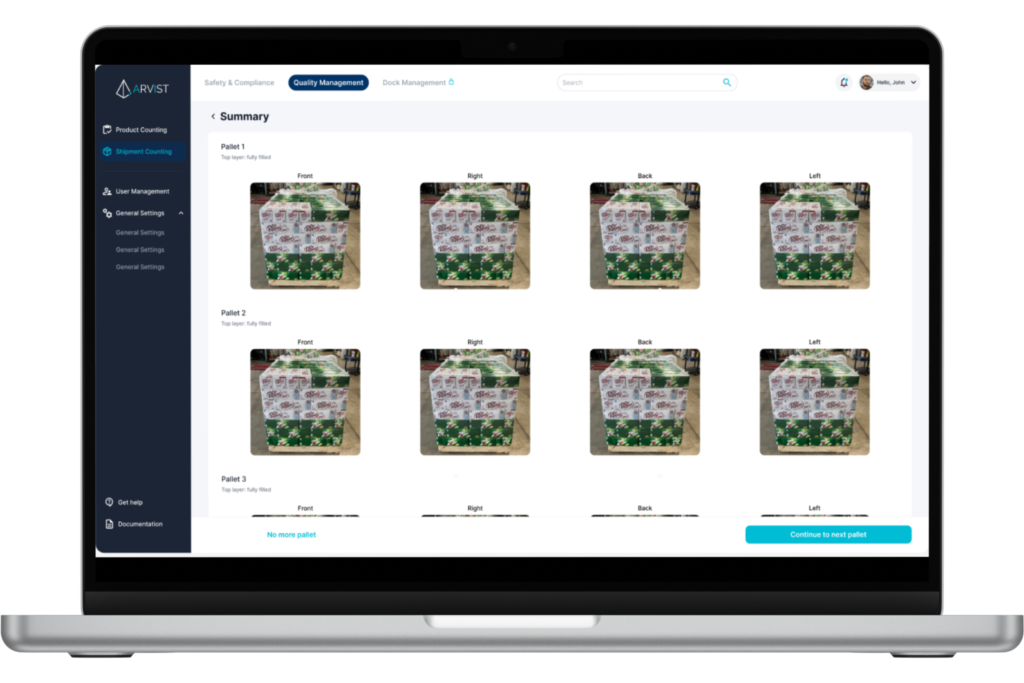

In a real-world application, the Arvist AI solution exemplifies the benefits of computer vision in warehousing. At loading docks, this system allows workers to quickly capture images of pallets, which are then analyzed to flag products close to their expiry dates. This not only improves the accuracy of quality control but also leads to substantial savings on transportation costs and enhances client satisfaction by ensuring that only fresh, viable products are sent to retail locations.

Challenges and Solutions

Common Barriers to Adoption

One significant challenge in implementing computer vision in warehouses is the technology’s relative novelty, which may lead to initial bugs or glitches that need resolution. Additionally, the success of computer vision heavily relies on the quality and structure of data. It requires extensive, accurately labeled data to train the algorithms effectively. Furthermore, the environmental conditions in which computer vision operates, such as lighting and object variations, can significantly affect its performance. These factors combined make the deployment of computer vision systems complex and sometimes costly, especially considering the need for high-quality cameras and processing technology. Although these costs are way lower than manual methods of operations or using expensive sensors, deploying computer vision solutions do require a time commitment from both the operations and IT teams at the warehousing operations.

Strategies for Overcoming Challenges

To overcome these barriers, businesses can start by enhancing the clarity and condition of input images or videos, which are crucial for the accuracy of computer vision systems. Implementing robust data quality control measures, such as data cleaning and validation, is essential. Additionally, scalability can be addressed by adopting modular and scalable architecture and leveraging cloud-based infrastructure to reduce upfront costs. For real-time processing requirements, investing in powerful computing resources to minimize latency is critical. Computing resources does not equate to massive GPU based infrastructure in most cases but the ability to connect with servers, having high speed internet and working know-how about integrations within the warehousing IT environment is key to a successful computer vision based quality control process in a warehouse.

Conclusion

The emergence of computer vision in warehouse quality control heralds a significant shift towards operational efficiency and precision, underscoring the transformative potential of integrating advanced technologies in streamlining warehouse operations. A pertinent illustration of this integration’s impact is seen in the Arvist AI solution, which marks a real-world application where technology not only refines the quality control process but also achieves considerable savings on transportation costs and bolsters client satisfaction by ensuring the dispatch of fresh products to retail locations.

Such innovations, while showcasing the potential for immediate operational improvements, also propose a future where challenges such as data quality, system scalability, and environmental conditions are adeptly navigated through advanced solutions. The path forward involves not only the adoption of these technologies but also a commitment to overcoming the hurdles that come with such advancements. By doing so, businesses can fully harness the power of computer vision in revolutionizing warehouse operations, bringing us closer to a reality where supply chain visibility and operational excellence are not merely goals but the standards of industry practice. This journey toward integrating computer vision into warehousing operations not only exemplifies how cutting-edge technology can address age-old challenges but also sets a benchmark for future innovations in logistics and supply chain management.

In the ever-evolving landscape of warehouse operations, embracing technology solutions is essential to maintaining a competitive edge. By incorporating Arvist into your warehouse, you can transform your cell phones and tablet cameras into a quality control super power.

Contact our team today to learn more about how Arvist can revolutionize your approach to warehouse quality control or if you would like to learn more about how computer vision could be used in various aspects of your warehousing operations.