In my role as Head of Product at Arvist.ai, I’m proud to see Arvist taking the lead as a pioneer and market leader in using Vision AI and Large Video Models (LVM) to transform Health, Safety, and Environment (HSE) and set new safety and compliance standards for warehouses around the world.

Vision AI has already transformed how HSE professionals and warehouse safety directors operate, and with the advent of large video models, we are on the brink of a new era of opportunities that promise to take warehouse safety and compliance to unprecedented levels.

Vision AI: The Foundation of Proactive Safety and Compliance

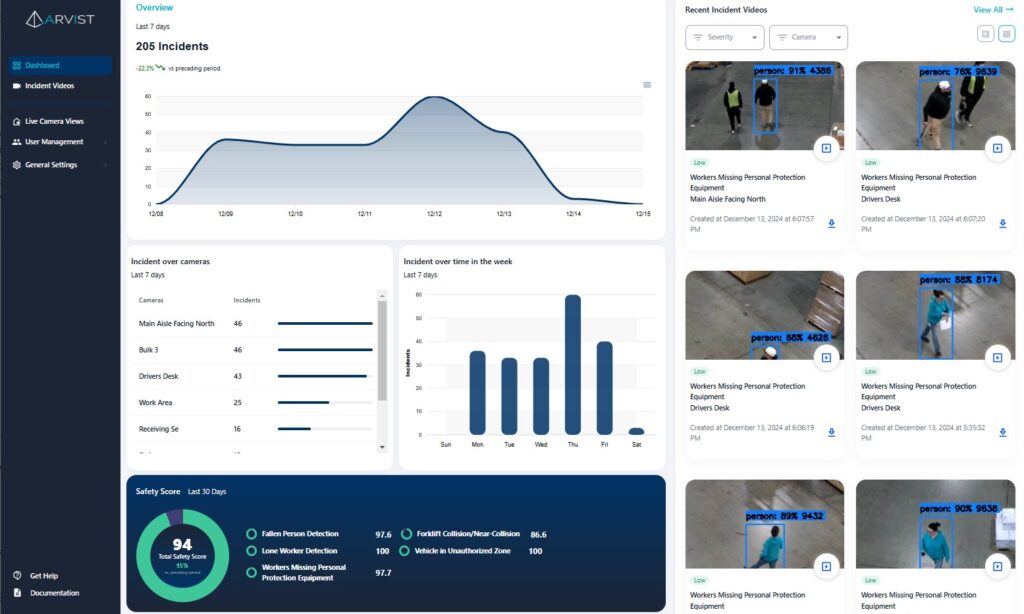

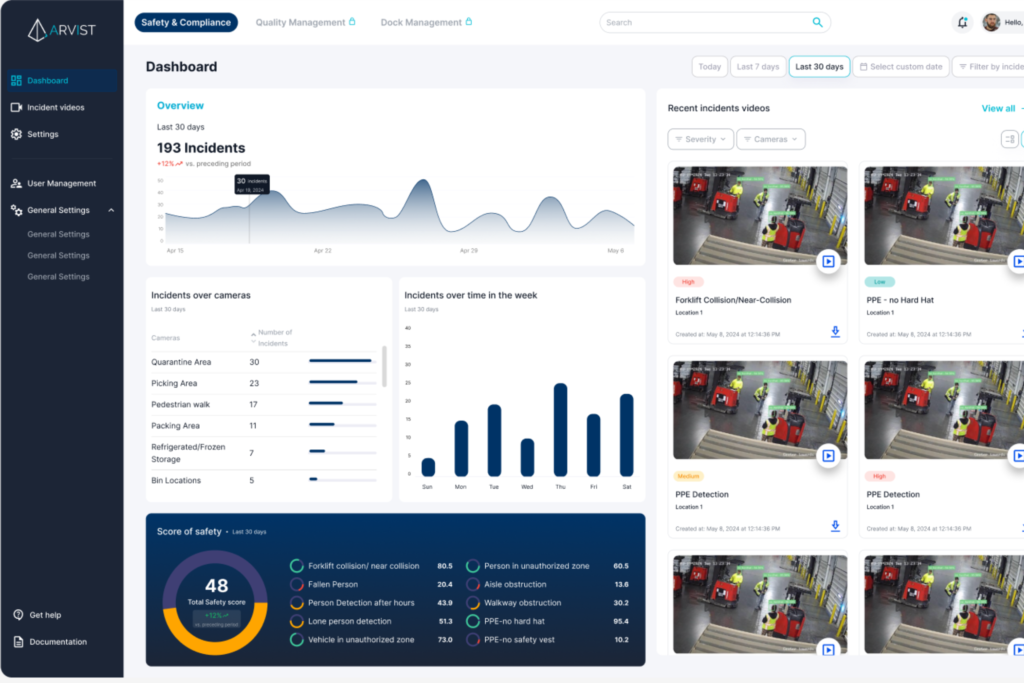

Vision AI has revolutionized safety and compliance in warehouses by automating the detection of safety-related incidents such as workers not wearing Personal Protective Equipment (PPE) or forklifts near collision scenarios. These advancements have equipped HSE professionals and warehouse safety directors with the ability to:

- Be Proactive, Not Reactive: Vision AI allows safety personnel to address potential hazards before they escalate into serious incidents.

- Gain Full Visibility: By transforming existing security cameras into ‘smart’ virtual safety inspectors, Vision AI provides comprehensive monitoring of safety and compliance incidents across the warehouse.

- Leverage Data Analytics: Automated monitoring aggregates data to enable data-driven decision-making, allowing HSE professionals to identify trends, assess risks, and implement corrective actions effectively.

This transformation from traditional, reactive safety measures to proactive, data-centric safety management has made Vision AI an indispensable tool in modern warehouse environments.

The Essentials of Vision AI: Object and Situation Detection

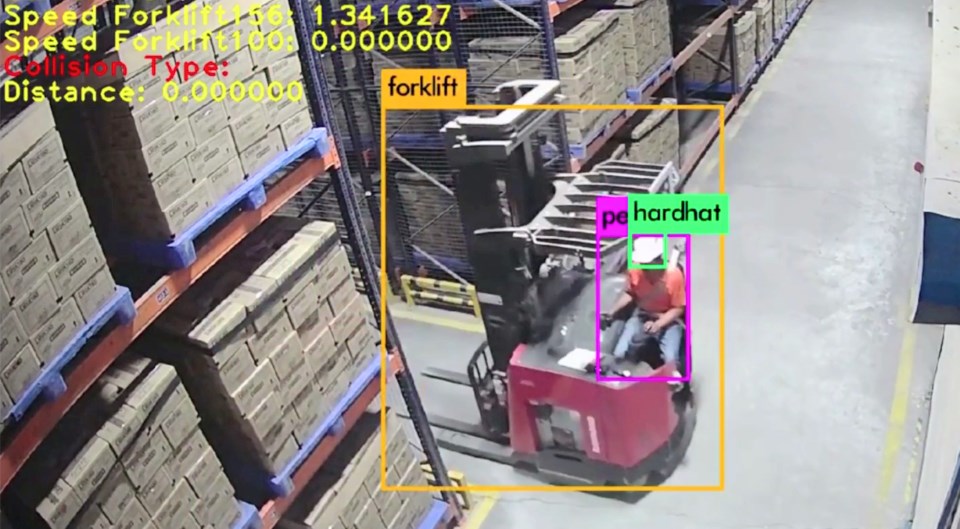

At the core of Vision AI’s success in enhancing safety and compliance is its ability to identify related objects and safety-critical situations, such as:

- Forklifts and Workers: Recognizing forklift movements and worker presence to prevent near-miss incidents.

- PPE Usage: Monitoring whether workers are wearing the required PPE, such as helmets, gloves, and safety vests.

Traditionally, these detections have relied on pre-trained vision models, like YOLO (You Only Look Once), which require extensive datasets featuring a rich variety of images. These images must cover different angles, distances, colors, and models to train the AI effectively.

Challenges with Traditional Vision AI Approaches

While traditional models have laid a solid foundation, they come with challenges that can limit the flexibility of detecting diverse safety-related scenarios, including:

- Specific Situations: Detecting incidents like a distracted worker speaking on the phone, a forklift parked with its fork up, or a worker fallen on the ground demands specialized datasets.

- Data Collection: Acquiring large, diverse datasets for each specific situation is often not trivial. The availability of images for particular incidents can be scarce, and assembling a comprehensive dataset can take months.

- Resource Intensity: Training and maintaining multiple specialized models for different scenarios can be resource-intensive and complex.

New Opportunities with Large Video Models

Enter Large Video Models (LVMs)—a game-changer in the Vision AI landscape. These models provide the flexibility to identify various safety-related situations without the need for a pre-trained, scenario-specific dataset. This approach opens up new possibilities, such as:

- Enhanced Detection Capabilities: LVMs enable the detection of a broader range of safety incidents, including niche and uncommon scenarios that would be challenging for traditional models to recognize.

- Industry-Specific Adaptations: From pharmaceutical warehouses to bottle packaging and air cargo terminals, LVMs allow for customized safety detections tailored to specific logistics site needs.

- Speed and Flexibility: With LVMs, deploying new safety detections is faster and more adaptable, reducing the dependency on lengthy data collection and model training processes.

Balancing Efficiency and Resource Management

While LVMs bring remarkable flexibility, they also present new challenges in managing resources wisely. Efficiently integrating local models with LVMs requires smart allocation to ensure that:

- Resource Use is Optimized: Balancing the load between local and large models to avoid overuse of computational resources.

- Detection Efficiency is Maintained: Ensuring that safety detections are not compromised by the integration of more complex models.

At Arvist , we are committed to leading the charge in this domain by continually pushing the boundaries of what Vision AI can achieve in HSE and safety & compliance. Our technology turns conventional security cameras setups into sophisticated, intelligent safety ecosystems, driving unparalleled improvements in warehouse operations.

Arvist AI: Leading the Way in Vision AI and Large Video Models

As a global vendor, Arvist.ai remains at the forefront of HSE and safety & compliance technology solutions. Our commitment to innovation, combined with our expertise in Vision AI and LVMs, empowers warehouses worldwide to enhance safety and compliance, improve quality control, and optimize operations. By integrating these advanced technologies, we’re not just keeping warehouses safe—we’re making them smarter, more efficient, and fully data-driven.

The future of warehouse safety and compliance is here, and it’s powered by the next generation of Vision AI. Together, let’s continue to transform warehouses into safer, more efficient workplaces with the groundbreaking potential of Large Video Models.