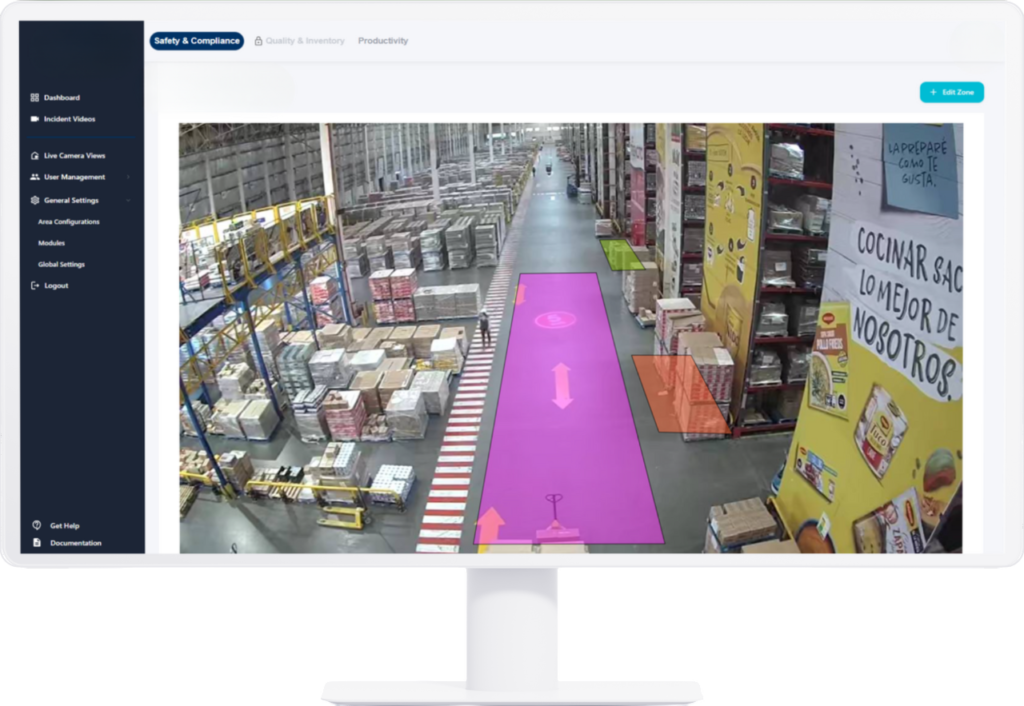

Arvist creates a visual system of record for packaging, labeling, and pallet builds before orders leave your facility.

Arvist QC in a Box™

See every pack-out and shipment

Arvist captures how orders are packed, labeled, palletized, and staged as they move through the warehouse, giving teams visibility into every step without relying on end-of-line audits or assumptions.

Objective proof for every order

Time-stamped visual records provide reliable evidence that packaging, labeling, and pallet builds meet retailer requirements, eliminating the need to chase photos, emails, or tribal knowledge.

Catch issues before they ship

Arvist flags exceptions in real time when builds, labels, or pallets fall outside defined retailer specifications, allowing teams to correct errors before trailers leave the dock and costly penalties occur.

Your system of record for compliance

Every order leaves the warehouse with a verifiable visual trail tied to retailer rules, reducing chargebacks, supporting audits, and building long-term operational trust.

The ROI of getting loads right

Arvist delivers proven results where precision, efficiency, and uptime matter most.

40–60%

Lower packing error rates

40–60%

Fewer error-driven tickets

3–4 mo.

ROI payback

AI That Moves your Warehouse

Packing Table Station

No matter your warehouse objectives, Arvist’s AI-powered inspections deliver real, trackable benefits today. Validate outbound orders for retail compliance — ideal for pack out, labeling, and palletization.

Captures every carton and pallet as it moves through the packing table for complete visual coverage.

Confirms the correct SKUs, quantities, and labels are applied and visible for each order.

Connects with WMS and other enterprise systems so compliance evidence and exceptions appear where teams already work.

Captures time-stamped photos, detects labeling or packing exceptions, and creates a visual record automatically.

Reduces pack errors, invalid “missing item” claims, and chargebacks while supporting audit-ready shipments.

Supports validation across multiple packing lines and outbound stations.

How it works: From Pack-Out to Outbound

See how Arvist ensures every load meets retailer standards, reduces errors, and feeds visual proof directly into your compliance workflows.

1. Install Arvist QC in a Box

Drops into your existing processes in hours and uses standard cameras to track order flow at inbound and outbound.

2. Set retailer rules

Retailer-specific requirements are configured in Arvist so every order is automatically checked against the correct standards.

3. Flag issues early

Real-time monitoring alerts teams to out-of-spec builds before shipments are sealed and penalties occur.

4. Review and resolve

Time-stamped records create a visual audit trail and use AI to automate dispute resolution, supporting faster audits and chargeback management.

FAQs

You’ve got the questions, we’ve got the answers.

Warehouse retail compliance ensures orders are packed, labeled, and staged according to retailer specifications, helping prevent chargebacks, rejected loads, and scorecard penalties.

Arvist provides real-time monitoring and visual proof of every order, flagging deviations in labeling, carton assem

Arvist monitors packing accuracy, label placement and visibility, pallet patterns and height, carton specs, and order completeness, covering the most common retailer penalties.

Yes. Arvist connects to your WMS and compliance workflows, feeding time-stamped visual evidence directly into operational and chargeback processes.

Warehouses using Arvist typically see fewer chargebacks, reduced rework, faster exception resolution, improved on-time and in-full performance, and stronger retailer scorecards.

Customers start by connecting cameras at pack-out, palletization, and staging areas, defining retailer-specific rules, and streaming real-time exceptions to supervisors, often beginning with high-penalty retailers and rolling out to all lanes.

From manual checks to automated intelligence — that’s Arvist.