Arvist captures real movement, timing, and condition so costly mistakes get caught before they leave your network.

Arvist QC in a Box™

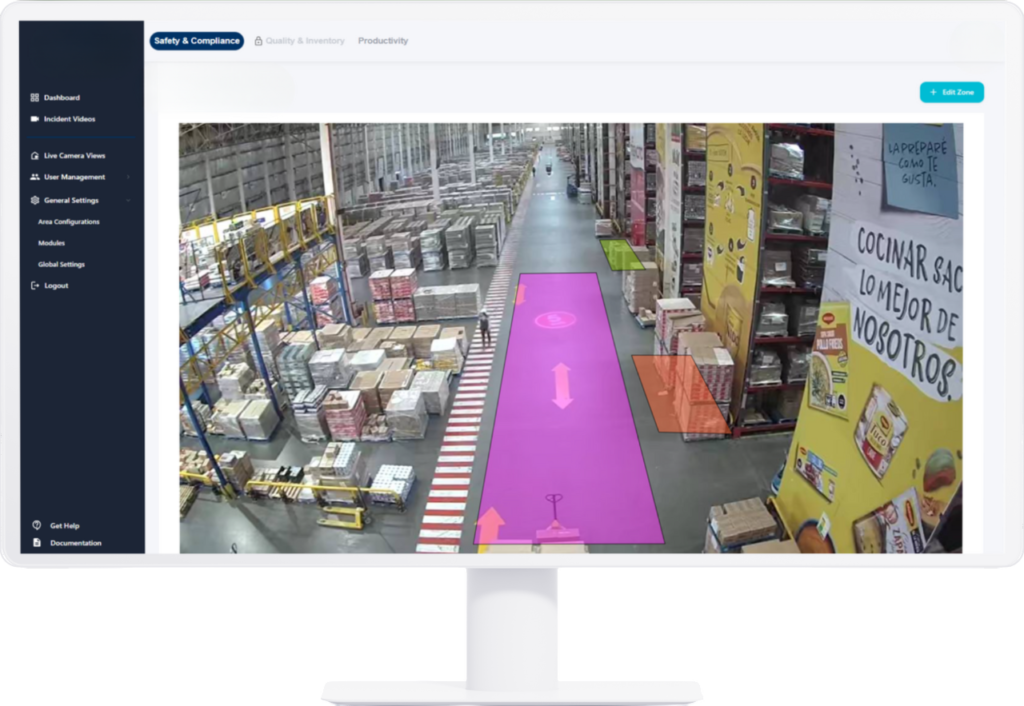

See everything on the dock

Automatically track pallets and boxes as they cross the threshold, monitor doors opening and closing, and capture when loading actually starts and finishes.

Capture real-time load conditions

Detect visible issues like crushed corners, unstable stacks, or broken wrap and record it all with time-stamped, visual proof.

Measure exactly what moves

Compare pallet counts to your BOL, log door events, and track load-complete timestamps for a precise record of every shipment.

Connect where it matters

Integrates with WMS/TMS for real-time status and block-ship rules, feeds claims workflows with evidence packets, and powers dashboards for operations, transportation, and customer teams.

The result

A single, authoritative system of record for what was loaded, when, and how. Every load is captured with visual proof, timestamps, and exception tracking, reducing disputes, improving efficiency, and making audits or customer inquiries fast and reliable.

The ROI of getting loads right

Arvist delivers proven results where precision, efficiency, and uptime matter most.

50%

25-35%

Lower load damage rates

30-50%

Fewer mis-loads and mis-docks

6-12 mo.

ROI payback

AI That Moves your Warehouse

Conveyor Station

No matter your warehouse objectives, Arvist’s AI-powered inspections deliver real, trackable benefits today. Validate labeling, SKU, and quantity for items on the conveyor.

Four cameras (top, left, right, back) capture every item for complete visibility.

Confirms each item has the correct label and SKU before it moves downstream.

Ensures the correct number of items per order.

Seamlessly connects with WMS and other enterprise systems for real-time updates.

Captures photos, detects exceptions, and automatically produces damage claims.

Minimizes mis-picks, labeling errors, and costly discrepancies.

Drive-Through Station

No matter your loading or unloading workflows, Arvist delivers real, trackable value. Real-time inspection verifies the right loads, in the right quantities, during loading and unloading—reducing errors, disputes, and rework.

Four cameras (top, left, right, front) monitor each load in real time.

Confirms the correct license plate numbers, SKUs, and quantities for each load.

Connects with WMS and other enterprise systems to keep all teams updated.

Captures photos, detects exceptions, and automatically produces damage claims.

Reduces misloads, short/over-ships, and costly disputes.

Supports inspection across multiple lanes and loading points.

FAQs

You’ve got the questions, we’ve got the answers.

It confirms the right products, quantities, and conditions leave your warehouse, preventing errors and protecting margins.

AI-powered cameras track pallets, boxes, and door activity in real time, capturing counts, conditions, and timestamps.

Yes. It connects with WMS, TMS, claims workflows, and dashboards for real-time visibility.

Mid-size DCs typically save $250K–$300K per year, reduce short/over-ships (~50%), mis-loads (30–50%), and load damage (25–35%).

Many installations take less than a month. Station setups typically require 1 day to connect to existing network infrastructure.

Yes. Multi-angle cameras capture damage and automatically produce claims for faster resolution.

From manual checks to automated intelligence — that’s Arvist.