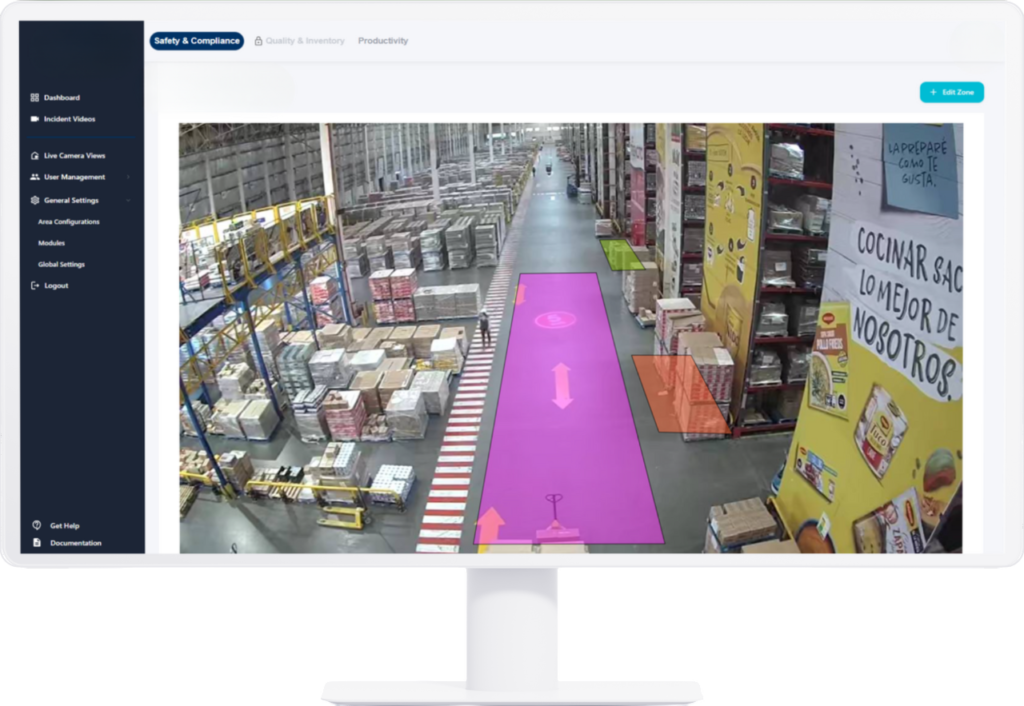

What happens when AI hits the warehouse floor? See it live in the Arvist Experience Center.

See AI in action on the warehouse floor

Book Your VisitYour warehouse should protect employees and operations without slowing down productivity.

Arvist provides intelligent oversight across your warehouse, so you can reduce risk, protect employees, and keep operations moving.

Arvist monitors forklifts, workers, and emergency zones in real time so risks are caught before they become accidents.

AI detects PPE violations across your warehouse, keeping employees safe and standards enforced without manual checks.

Identify high-risk zones, track near-misses, and reduce accidents between workers, forklifts, and inventory.

Arvist analyzes movements to flag ergonomic risks, lowering workplace injuries and improving overall well-being.

Track trends, identify risks, and monitor compliance effortlessly across your entire warehouse.

Arvist delivers proven results where precision, efficiency, and uptime matter most.

When accuracy matters, warehouses choose Arvist for intelligent, automated insights.

Automate Quality Checks to meet Highest Standards

At USI, our commitment to excellence drove us to partner with Arvist. Their vision technology has not just met but exceeded our expectations, revolutionizing how we approach safety, compliance, and inventory control. With real-time safety tracking, AI-powered inspections, and automated quality checks, we're not just processing goods; we're ensuring they meet the high standards our clients deserve. This partnership has elevated our operations, enhancing both efficiency and client satisfaction.

Transform Safety & Ergonomics Monitoring

Arvist has done a fantastic job helping Holmatro see opportunities to utilize AI software. They originally came in to help with safety and ergonomics and ended up helping improve our building security and receiving process. They were very patient with us and listen to our needs. The software engineers not only took our information and created something great but they also added features we didn’t think possible. They have really gone above and beyond what we originally thought possible.

You’ve got the questions, we’ve got the answers.

Arvist uses AI-driven vision and analytics to monitor warehouses in real time, detecting hazards, PPE violations, unsafe behaviors, ergonomic risks, and compliance issues before they become incidents.

By analyzing video feeds from existing security cameras or installed cameras, Arvist flags issues like near-misses, collisions, blocked emergency zones, unauthorized zone entry, and other unsafe conditions automatically.

Yes. The system can detect PPE violations, such as missing hard hats or vests, and alert supervisors in real time, reducing reliance on manual checks and increasing compliance consistency.

Yes. Beyond hazard detection, Arvist monitors worker movements to identify ergonomic risks, such as unsafe lifting or repetitive strain, helping reduce injuries and improve workplace well-being.

Arvist delivers analytics dashboards, safety scoring, incident logs with video or photo evidence, heat maps of high-risk zones, and trend reports, letting safety managers see patterns, recurring risks, and overall compliance performance over time.

No. Arvist is designed to work with your existing infrastructure, including cameras and WMS or ERP systems. It runs alongside current workflows without major process changes or downtime.

Deployment is fast. Many warehouses go live within a day per safety or compliance station. Because the platform integrates with existing hardware and data streams, long-term IT overhauls are not necessary.

© 2026 Arvist. All rights reserved | Designed by Moonshot Advisory